Is Keela one of the most important outdoor brands you’ve never heard of?

We take a tour of Scottish hiking brand Keela’s factory to find out why they keep making their garments at home, and how they’ve continued to grow despite the odds

All the latest inspiration, tips and guides to help you plan your next Advnture!

You are now subscribed

Your newsletter sign-up was successful

These days, when you pick up a new waterproof jacket or base layer for hiking, you probably assume that it was produced in a factory in some far-off corner of the world, and that’s usually true. Manufacturing goods offshore is a hallmark of globalization, and as much as I want my hiking boots and fleece jacket to be made here at home to reduce my carbon footprint as a hiker, I’m all too aware that my love of exploring nature also leaves its mark.

So you can imagine my surprise when I discovered that an outdoors brand was making hiking gear just down the road from me. Keela has been quietly making clothing for the outdoors here in Scotland for over 30 years, and I recently visited their factory to meet with Marketing and Technical Coordinator Grace MacGregor and discover more about this homegrown operation. By the time my visit was over, I had the distinct impression that Keela is one of the most important outdoor brands you may never have heard of.

Keela’s headquarters, also its manufacturing facility, is located in an unassuming town named Glenrothes in the east of Scotland. I arrive there one sunny morning in late January after just over an hour’s drive from home and find it in an unremarkable but welcoming enough industrial estate. I’d visited GORE-TEX’s Scottish plant months before, which turned out to be a largely vacant building, so honestly, my expectations were low. Once indoors, however, I discover the place is a humming hive of activity.

“It’s great here,” says MacGregor, who studied fashion design and worked in retail before joining the team here a couple of years ago.

“With it being a family-owned business, you get to experience all different aspects of the business that you normally wouldn’t,” MacGregor says, describing how she went from sewing hospital gowns during lockdown to handling marketing and website design.

Keela is owned by Ardmel Automation, a specialist engineering and manufacturer also based in Glenrothes, and upon learning this, I realize I’m onto something big. It turns out that Ardmel revolutionized how we make waterproof clothing, chartering the course for our ability to stay safe and comfortable when we’re adventuring in wet weather.

“We’re basically a one-stop shop”

If you’re anything like me, when you see clouds forming in the distance, you don’t cancel your hiking plans; you just pull on your waterproof jacket and rain pants and head out anyway, safe in the knowledge that they’ll keep you dry and warm. One of the key aspects that makes something like a waterproof jacket waterproof – taped seams – is made possible thanks to the MK-1 Seam Sealer machine, which was invented right here by Ardmel founder and engineer Rube Fernando back in 1979.

All the latest inspiration, tips and guides to help you plan your next Advnture!

“Before the seam sealing machine there would be big massive rooms full of ladies with big sheets of fabric and they’d be dabbing lots of glue to seal the seams,” explains MacGregor, describing a process she says was “obviously very toxic” from a health and safety standpoint as well as time-consuming, labor-intensive and inconsistent in its results.

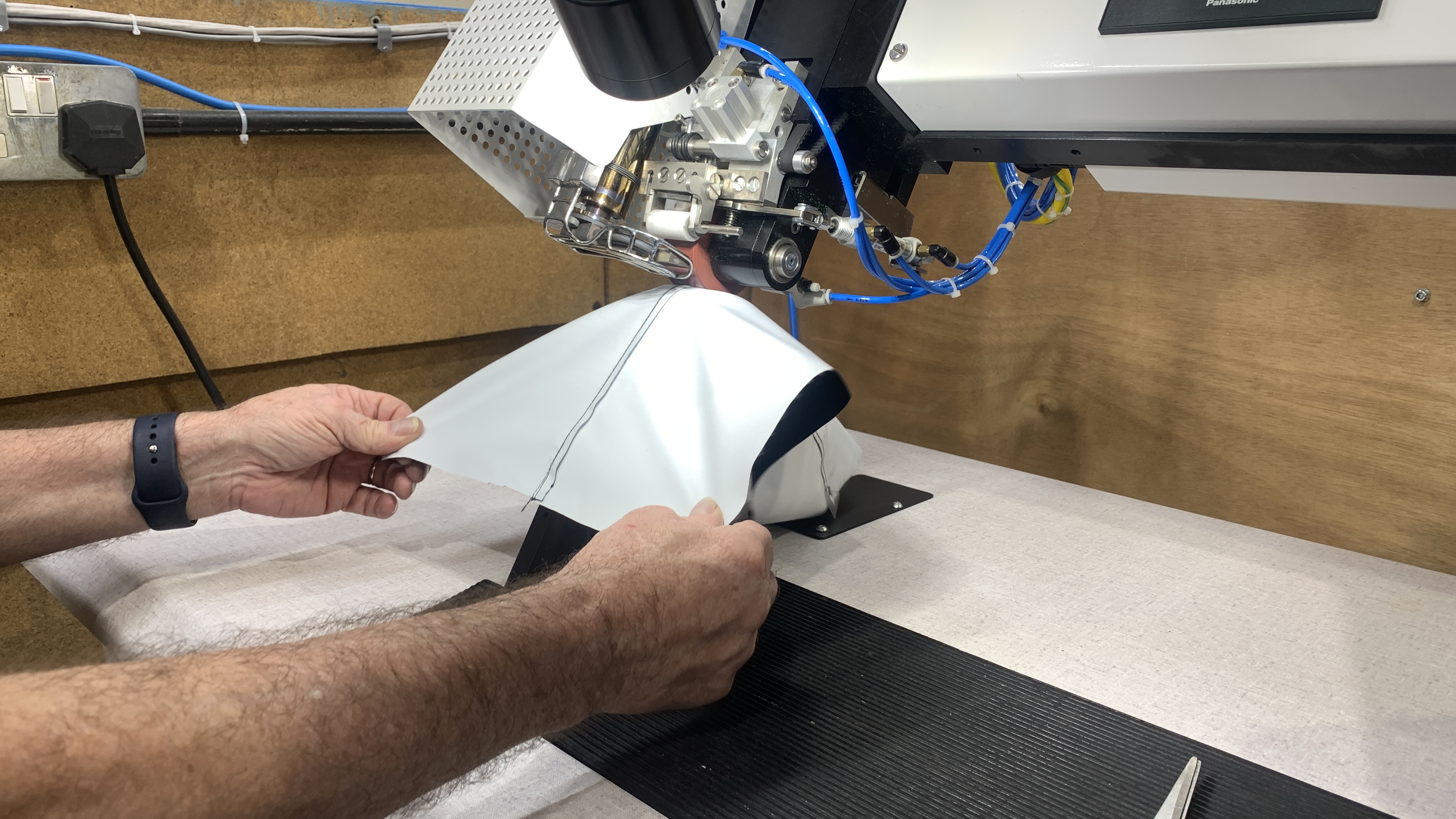

Sri Lanka-born Fernando decided to pioneer a mechanical approach to seam sealing, and his machine caught the eye of other outdoor brands at the time. Ardmel’s seam sealing machine was safer, more efficient and easy to use – something I can attest to after giving it a go during my visit – and quickly, other outdoor companies such as Barbour acquired an MK-1 from Ardmel for their own facilities. These days, the machine is on its fifth iteration and is still helping companies across the globe produce waterproof garments.

It was only a matter of time before an innovator like Fernando realized he could be using the machine to make his own waterproof gear, and in 1989, Keela was born, initially designing clothing for mountain rescue teams before launching the world’s first fully tape-sealed fleece jacket in 2001. Today, the company designs and makes jackets and hiking pants, mid layers, base layers and accessories for hiking and running, with many items being manufactured right here in Glenrothes. Others are made in Keela’s Sri Lanka facility.

A few minutes after receiving this impressive oral history from MacGregor, I find myself standing over the MK-1, being shown the ropes by Wullie Daly, technical support service manager at the plant. He’s worked here for 21 years and knows everything about the dozens of machines all whirring and beeping away in the busy room.

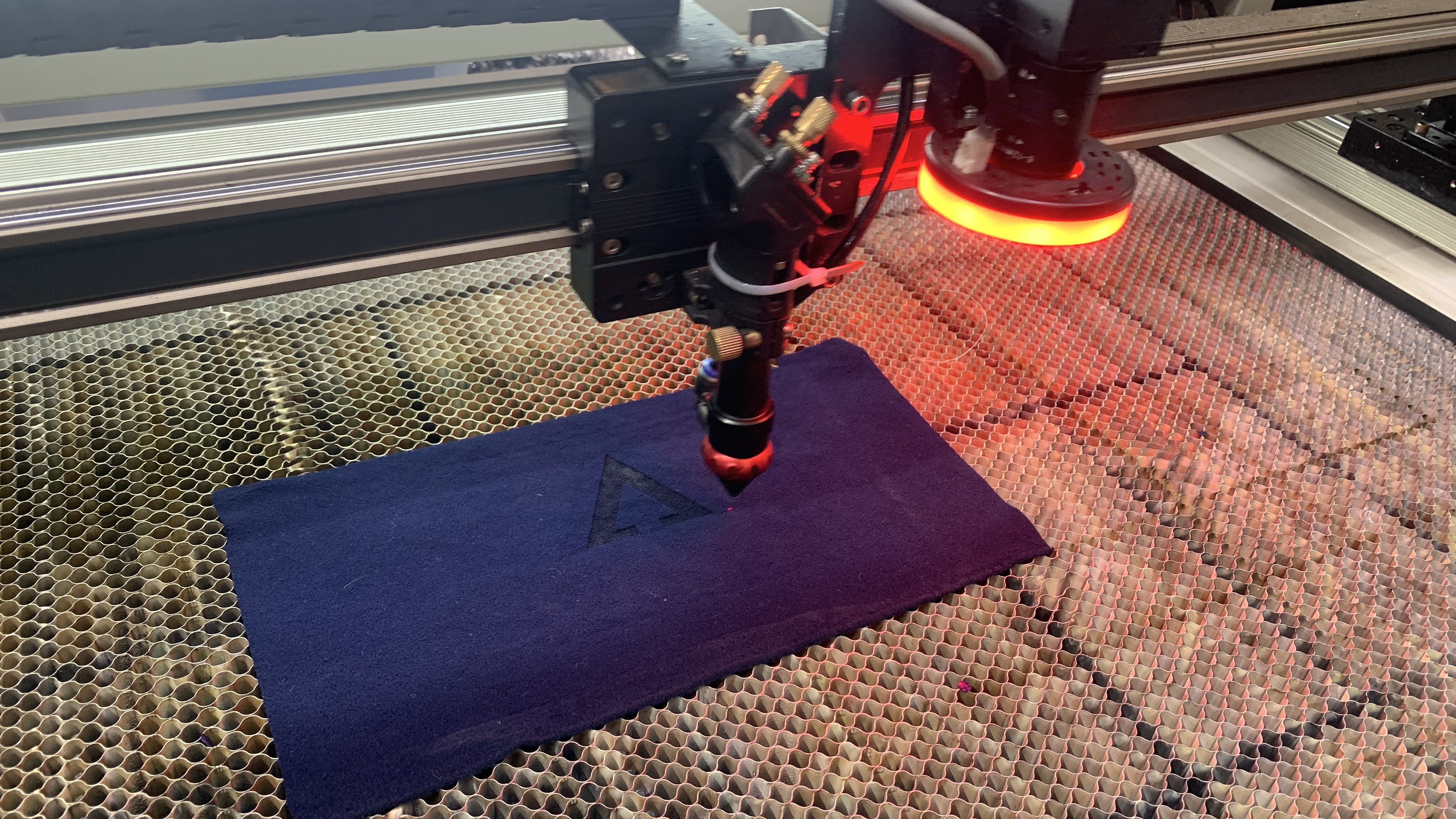

Among them are a hydrostatic head tester, which checks the waterproofing capabilities of a garment or tent, a laser cutter and engraving machine which embosses a piece of fabric with the Advnture logo before my very eyes in mere moments, and an ultrasonic jig cutter which ensures the company can cut material for garments without fraying and seal seams without stitching – these are services Ardmel performs for Keela as well as other brands and outfits, from the UK’s mountain rescue teams to Levi’s jeans.

“We’re basically a one-stop shop,” explains Daly, showing me how the plant can take a garment from design to delivery without outsourcing.

“Because we’ve got the experience in the garment industry, we can then apply all our equipment to making it and we know it all works.”

“And then COVID came along”

For many companies, COVID marked a period of rapid decline, and in the UK anyway, it was the cherry on the cake for many industries that have been decelerating for decades. But the pandemic had a markedly different effect on Keela and its sister company Ilasco, which takes care of sewing and production. In early 2020, the bustling factory I’m standing in now looked a bit different. Only two people remained in Keela’s sewing department and there were just four sewing machines left. Between the cost of in-house manufacturing and the pitfalls of Brexit, the company had all but given up on homegrown garment-making. Then the world changed.

“I had my own company making bridal alterations then COVID came along,” recalls Production Manager Nancy Wilson, whose business went the way of weddings during lockdown. “I saw they were looking for help here but I thought I was coming to be a volunteer.”

In fact, Wilson found herself joining a team of sewers to help make PPE equipment. Like Wilson, many had been laid off from their factory jobs 20 years ago, some from this very plant. Now they were back. At first, they were making body bags for victims of the pandemic. Wilson had to bring her own machine from home to keep up with demand. Then came a major PPE contract for hospital gowns and so began the factory’s second wind. They rented out a second factory space up the street and bought more machines to keep up with the demand. Their team grew to 60 employees working on 27 sewing machines; with their newly inflated facilities, they made 750,000 gowns that year.

“Rube kept swaying they’d keep us all on at the end of that contract,” says Wilson admitting she expected to be laid off again. But when the contract ended, Keela decided to keep making garments, and the team continues to grow.

“He did keep true to his word and kept us all on.”

“It’s more expensive, but people like it”

In the next room, I find dozens of people busily cutting and sewing every garment imaginable, from first responder uniforms and doggy robes to Keela’s line of changing robes for wild swimming and waxed cotton jackets for hiking. The crew makes it all look effortless, but the people I meet assure me that there are challenges.

First of all, producing garments in the UK means ever-increasing costs, which necessitates a balancing act for the company in maintaining their values whilst ensuring they can continue financially. There is often a long wait for materials – “even getting certain types of technical zips in the UK can be super hard,” explains MacGregor.

You’ve also got the fact that as a small company, Keela doesn’t sell out of designs as quickly as major brands, so with the tides turning towards PFC-free DWR treatments and more environmentally-friendly membranes, they could be faced with ending up with a backlog of garments they can’t as easily offload.

Despite these hurdles, they remain intent on keeping at least some of their production in-house.

“It’s more expensive, but people like it, they want it made in the UK,” muses MacGregor.

When it comes to innovation, they’re keeping pace with bigger brands, introducing their first women’s only designs and working on plans to increase their sizing to plus sizes to accommodate all types of hiker, something that Design and Garment Technologist Steph Whelan tells me isn’t as simple as just making a bigger version of the same pattern. People with bigger hips don’t necessarily have bigger wrists, so jackets need to be designed with a whole new body in mind.

“Once you get to a certain size, the body doesn’t change in the same way so it can’t just be a blanket cut. You actually need to make sure you’re fitting on people who are that size, rather than just assuming it will fit which I think is where a lot of brands struggle,” says Whelan, who is working with an organization called Every Body Outdoors to ensure they get that perfect fit.

“It’s got a good story behind it”

It’s time for the last stop on my whistle-stop factory tour and we’re talking about sustainability. Let’s be honest: in 2024, every outdoor brand is shouting from the rooftops about what they’re doing to help save the planet, and every one of them wants you to think it invented sustainability, but Keela really is one of the earlier adopters. In fact, the roots of the Keela clothing hospital, which carries out kit repairs, lie in the company’s Repair Center, which was launched over 40 years ago and predates Keela itself.

“Recently it’s got a lot busier with people wanting to repair their kit rather than buy something new,” MacGregor tells me, holding up a jacket they’re refreshing for a customer. It was made here at the factory back in the 1990s and still looks in great shape. The owner just wants them to replace the hood so they can keep wearing it.

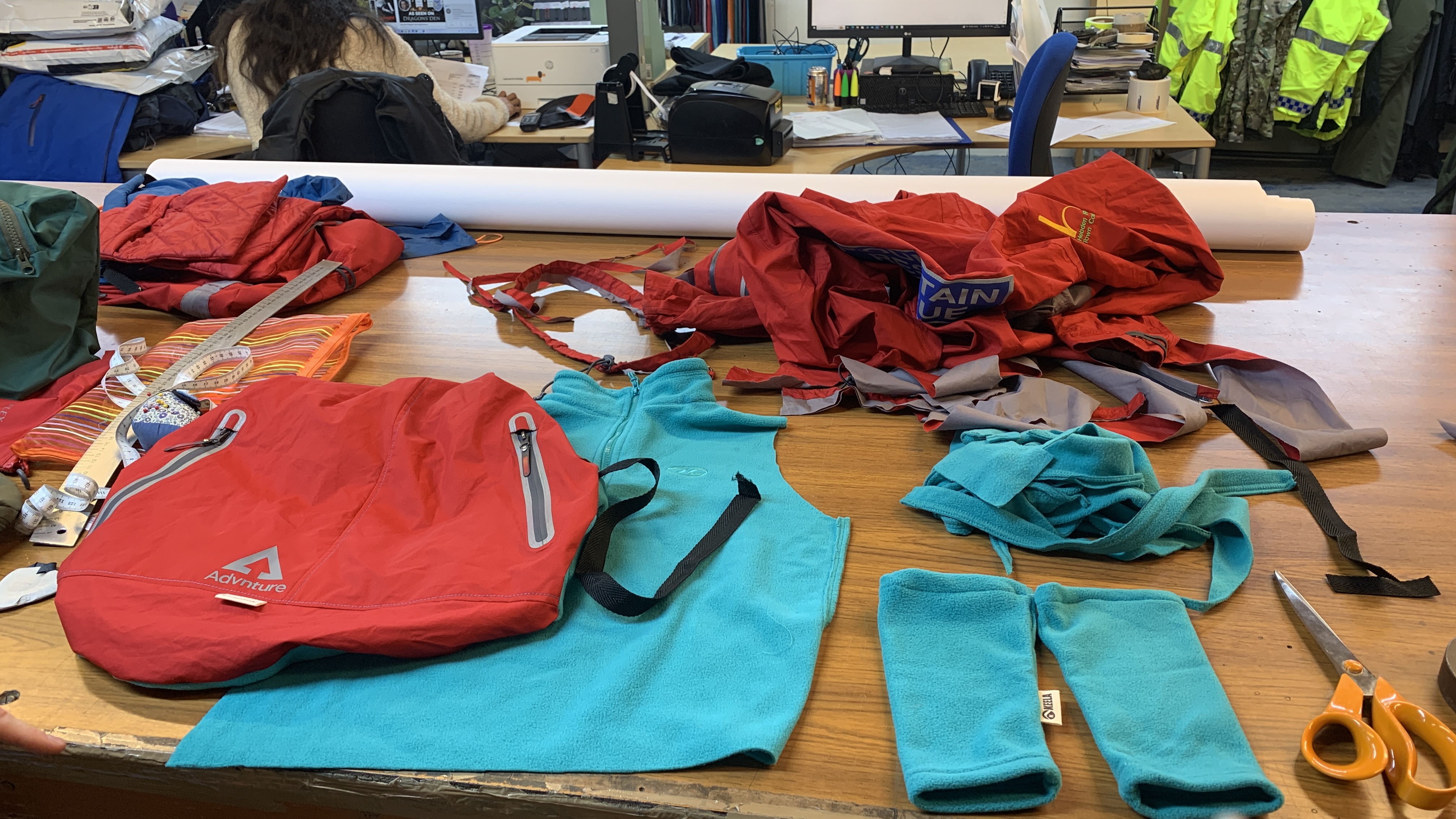

Keela’s Legacy Project also involves innovative recycling and upcycling programs that can turn items like your old rain jacket into a toiletry bag, duffel bag or doggy backpack. In the couple of hours that I’m here, their talented intern Sasha transforms my old fleece into a doggy jacket, a pair of mittens and a wash bag. They’re also in the early stages of providing instructions for people to carry out these craft projects at home.

Newer ventures include selling blueprint designs that never quite made it to retail as one-off items and creating short runs of limited edition garments that use up old rolls of fabric. The end result is very little in the way of waste, and a lot of cool designs, such as a colorful patchwork ski jacket called Mix Tape made using end-of-line pieces that will be ready for next year’s ski season.

“It’s got a good story behind it. Although it’s probably not going to be the biggest seller for us, it’s going to be made in the UK, using fabric that would have otherwise just gone to scrap,” says Whelan.

It’s clear that a history of innovation is what got Keela where they are today, but it’s a commitment to investing in sustainability and community that’s going to keep them moving forward. Before I start up my car to leave, I record the following voice note to myself: if you love the outdoors, Keela is exactly the brand that you want making the clothes that keep you safe while you’re out there.

Julia Clarke is a staff writer for Advnture.com and the author of the book Restorative Yoga for Beginners. She loves to explore mountains on foot, bike, skis and belay and then recover on the the yoga mat. Julia graduated with a degree in journalism in 2004 and spent eight years working as a radio presenter in Kansas City, Vermont, Boston and New York City before discovering the joys of the Rocky Mountains. She then detoured west to Colorado and enjoyed 11 years teaching yoga in Vail before returning to her hometown of Glasgow, Scotland in 2020 to focus on family and writing.